Before exploring what moisture content in wood actually is, let’s first take a moment to understand how wood is formed. It all begins with a tree—living, growing, and thriving with energy.

The Journey of Timber: From Tree to WoodTimber, which is just another name for wood, has a fascinating journey before it ends up in our homes. It begins with trees, which grow by absorbing nutrients and water from the soil. The water that flows through the tree helps carry those nutrients, keeping the tree alive and healthy.

When a tree falls or is cut down and turned into timber (wood), it still holds onto the water it collected when it was alive. Even after the tree is no longer growing, the water stays inside the wood, and that’s an important part of the wood we use today.

Wood and Moisture: A Special RelationshipWood has a special ability. It’s hygroscopic, which means it can absorb and release moisture from the air around it. If the air is humid, wood will soak up the moisture. If the air is dry, wood will release some of the moisture back into the air.

That’s why even after a tree is turned into lumber for building homes or making furniture, the moisture inside the wood continues to change depending on the weather. Wood always has a little bit of water inside it, and it’s constantly adjusting to the environment!

What is the impact of moisture in wood?

Moisture content is crucial when it comes to wood, as it has a significant impact on how the wood behaves over time. For instance, if the wood absorbs too much moisture, it can swell or warp, while if it loses too much moisture, it may crack or shrink.

Seasonal changes in temperature and humidity will always affect the moisture content of wood. During the warmer months, humidity tends to be higher, causing wood to absorb moisture and expand. In the colder months, the air becomes drier, leading to a loss of moisture and a shrinkage of the wood. These natural cycles can be challenging when working with wood, especially in furniture-making, construction, or flooring.

However, you can ensure the best results by choosing wood with an appropriate moisture content for your project. Wood that has been properly dried and is at a balanced moisture level is less likely to shrink, expand, or warp. Throughout its service time, it needs to be managed to ensure it does not deteriorate over time and lead to fungal decay. Don’t worry, it is not as difficult as it reads! Just takes some simple care taking.

Seasoning Wood to Manage Moisture: Why It Matters

Moisture plays a crucial role in how wood behaves. If wood isn’t properly seasoned, the moisture inside can cause the following problems:

- Warping: Wood can bend or twist as it adjusts to drying out, leading to uneven surfaces.

- Cracking: As the moisture escapes, it can lead to cracks, especially if the wood dries too quickly or unevenly.

- Weakness: High moisture content can make wood more prone to decay, mold growth, and insect infestations.

- Shrinkage: As wood dries, it shrinks. If the wood is still too wet, you may notice it shrinking and changing shape as it adjusts to the climate in your home or outdoor environment.

Now that we’ve covered how and why moisture is naturally present in wood, it’s time to talk about one of the simplest and most effective ways to manage it—seasoning the wood before using it for your project. Seasoning is a process that reduces the moisture content of the wood, ensuring that it performs well over time and avoids issues like warping or cracking.

There are two main methods for seasoning wood:

1. Natural Seasoning AKA Air drying

In this method, wooden boards are stacked in a sheltered area, leaving space between each board to allow air to circulate freely. Over a period of 3 to 15 months, the wood gradually adjusts to the local climate and humidity conditions. During this time, the moisture in the wood naturally evaporates, and the wood reaches a more stable moisture content.

One key thing to remember is that natural seasoning should happen in the same location where the wood will be used. For example, if you plan to use the wood in Bangalore, it should be naturally seasoned in Bangalore. This ensures that the wood aligns with the specific humidity levels and environmental conditions of that area, making it more stable and durable when used in your project. This method is known to be the best way to control moisture in timber.

Advantages of Natural Seasoning:

- Cost-effective and low maintenance

- Allows the wood to naturally adjust to its environment

- Suitable for large quantities of wood

Disadvantages of Natural Seasoning:

- Time-consuming (takes several months)

- Requires ample space for proper stacking and airflow

- Exposure to the elements may lead to some weathering or potential pest infestations

2. Kiln Drying

Kiln drying is a faster, more controlled method. In this process, wood is stacked in a humidity-controlled chamber, where temperature and moisture levels are carefully managed. The goal is to match the humidity conditions of the location where the wood will be used but to achieve the desired moisture content much more quickly—usually within a few days to weeks. Kiln drying allows for precise control over the wood’s moisture content, which makes it an excellent choice for projects that require consistent and predictable results. It’s also faster, making it the preferred method for commercial timber and furniture production.

Advantages of Kiln Drying:

- Faster compared to natural seasoning

- More consistent moisture levels across different batches of wood

- Ideal for projects requiring specific moisture content

Disadvantages of Kiln Drying:

- More expensive due to energy costs and equipment

- Risk of drying too quickly, which can cause surface cracks or splits (if not done carefully)

- Requires professional equipment and expertise

How much moisture content in wood is ok?

Moisture in wood that matches the moisture of its application location is ok. This is the straight answer, now what does this mean? For wood to perform and service its intended application, it must align itself and match its environment. This matching of moisture content with its environment is called Equilibrium Moisture Content [EMC] and this impacts the density and performance of wood. In other words, it’s the point at which the wood neither gains nor loses moisture because it has adjusted to the humidity and temperature of its surroundings.

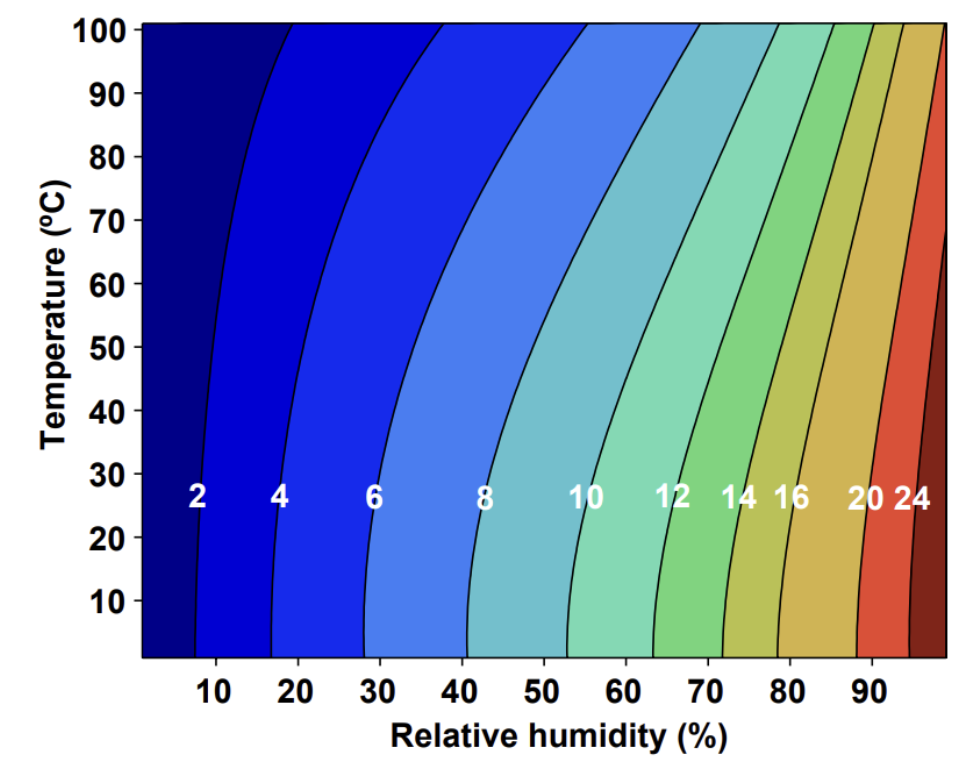

Image: EMC of wood as a function of relative humidity and temperature. Source: Wood Handbook, Wood as an engineering material 2010.

The EMC can vary depending on factors like temperature, humidity, and the species of wood. For example, in a typical indoor environment with a relative humidity of around 30-50%, the EMC of wood might range from 6% to 12%. This range of moisture content in wood is also suitable for use in Bangalore.

When it comes to hardwoods like Acacia, Teak, Mahogany, Honne, Ipe, Sal, Mathi, and other jungle woods from the tropical and sub-tropical regions of India, natural seasoning is typically preferred. This contrasts with the kiln drying (KD) method, which is more commonly used for imported softwoods such as Spruce, Pine, Fir, and other coniferous species. The natural seasoning process works best for these dense hardwoods, allowing them to adapt to the local climate and humidity, ensuring stability and durability in their final use.

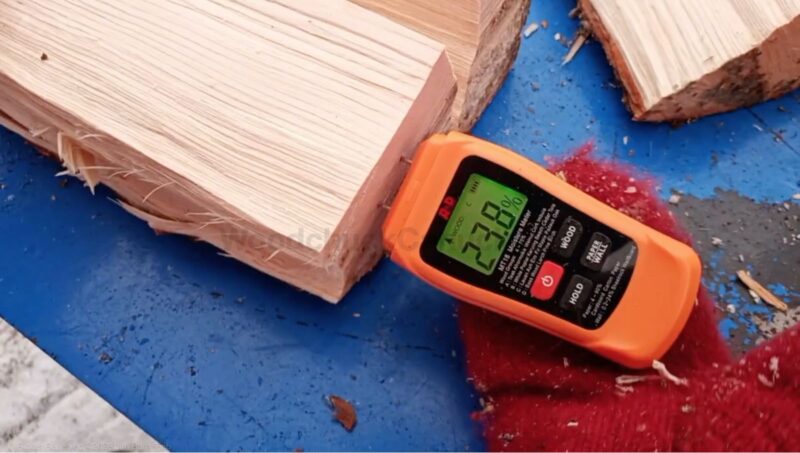

At Harsha Timbers, we specialize in stocking hardwoods sourced from the Indian subcontinent, which is primarily tropical and sub-tropical in nature. In addition to our locally sourced hardwoods, we also offer imported softwoods on request, all of which are carefully seasoned to moisture content levels of under 20%. This ensures that our customers receive high-quality, stable timber suited for a wide range of applications.

In summary, moisture content is key to wood’s behaviour, as it absorbs and releases moisture based on the environment, leading to expansion, shrinkage, or cracking. Seasoning, either through natural air drying or kiln drying, ensures stability. Natural seasoning allows wood to adjust to local humidity, while kiln drying speeds up the process. The ideal moisture content, or Equilibrium Moisture Content (EMC), depends on temperature and humidity. At Harsha Timbers, we offer both locally sourced hardwoods and imported softwoods, all carefully seasoned for optimal quality and durability.